plastic bottle thickness in mm

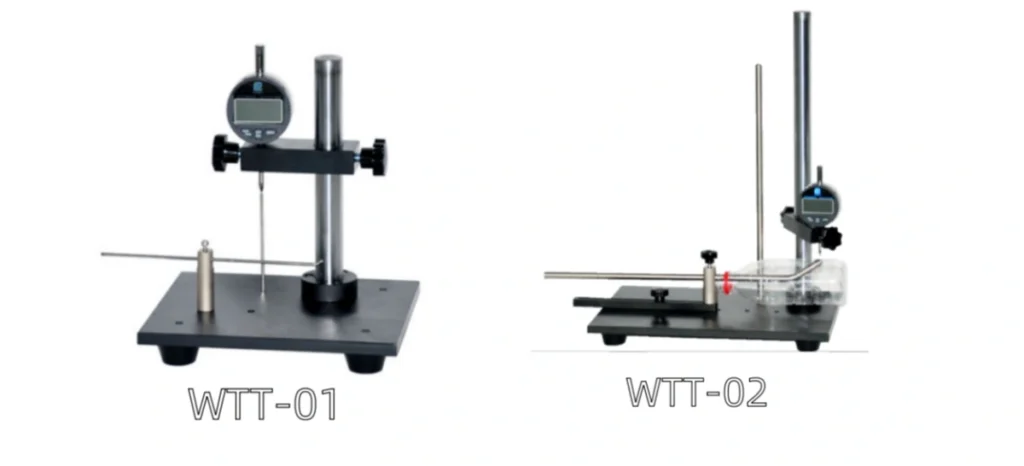

WTT Wall Thickness Tester

Bottle Wall Thickness Guide

About Us

Wall Thickness Tester

The WTT Wall Thickness Tester is a high-precision instrument designed to measure the wall thickness of plastic, PET, and glass bottles as well as various packaging containers. With advanced non-destructive testing technology, it provides reliable results for quality control, production optimization, and compliance with international packaging standards.

Thickness Tester Key Features

- High Accuracy Measurement – Delivers precise thickness readings within microns.

- Non-Destructive Testing – No need to cut or damage the sample.

- Wide Measuring Range – Applicable to PET bottles, glass bottles, plastic containers, and other hollow packaging.

- Digital Display – Clear, user-friendly interface with quick results.

- Compliance Standards – Meets ISO and ASTM testing requirements.

Wall Thickness Tester Applications

- Beverage Industry – PET bottles for water, soft drinks, and juices.

- Food Packaging – Edible oil, sauce, and condiment containers.

- Pharmaceutical & Healthcare – Medical bottles, vials, and containers.

- Cosmetics & Personal Care – Perfume bottles, cream jars, shampoo containers.

- Industrial Packaging – Chemical and cleaning product bottles.

Benefits of Using WTT Wall Thickness Tester

- Ensures uniform wall thickness for product durability and performance.

- Helps manufacturers optimize material usage and reduce costs.

- Improves quality control and compliance with international standards.

- Identifies weak spots in bottle design to prevent leakage or breakage.

- Increases production efficiency and customer confidence.

Technical Specifications

| WTT – 01 | Sample Diameter | 5 – 50mm (Customization available) |

| Test Range | 0 – 12.7mm | |

| Division value | 0.01mm / 0.001mm (optional) | |

| Measurable Height | 100mm (Customization available) | |

| WTT – 02 | Sample Diameter | 10 – 120mm (Customization available) |

| Test Range | 0 – 12.7mm | |

| Division value | 0.01mm / 0.001mm (optional) | |

| Measurable Height | 300mm (Customization available) |

bottle thickness measuring equipment

Why Choose Our WTT Wall Thickness Tester?

With proven accuracy, adaptability, and global support, the WTT Wall Thickness Tester ensures quality packaging, efficient production, and compliance.

1. Trusted Accuracy & Repeatability

Our WTT Wall Thickness Tester is engineered with advanced sensor technology to provide highly accurate and repeatable results. Each measurement is reliable down to the micron level, ensuring you can trust the data for quality control, design verification, and production optimization. Whether you are testing PET bottles, glass containers, or plastic packaging, the instrument consistently delivers precise readings that eliminate guesswork and reduce testing errors.

2. Customizable Solutions

We understand that packaging comes in different shapes, sizes, and materials. That’s why our WTT Wall Thickness Tester offers customizable fixtures and adaptable configurations, allowing seamless testing of various containers – from small medical vials to large beverage bottles. This flexibility ensures that one system can serve multiple product lines, helping manufacturers save costs while improving testing efficiency.

3. Global Support & Service

Choosing our WTT Wall Thickness Tester means gaining more than just an instrument – it means partnering with a team that provides global technical support, training, and after-sales service. We offer worldwide delivery and are committed to helping customers maintain peak instrument performance through calibration, software updates, and technical assistance. Our dedicated support ensures smooth integration into your production workflow and long-term reliability.

Thickness of Plastic Water Bottle

Importance of Wall Thickness Testing

Wall thickness testing is essential for ensuring the safety, efficiency, and compliance of packaging products. The importance of using a WTT Wall Thickness Tester can be explained from three major perspectives:

01

1. Product Safety & Performance

The wall thickness of a bottle or container directly determines its ability to withstand internal and external pressure.

- For carbonated beverages, insufficient wall thickness may lead to leakage or bursting.

- In pharmaceutical packaging, uneven thickness can cause contamination risks.

- For cosmetics and daily chemicals, weak walls can result in cracks and product loss.

Accurate thickness measurement ensures containers remain durable, safe, and reliable throughout storage, handling, and transportation.

02

2. Cost Control & Material Optimization

Packaging materials account for a significant portion of production costs. Without precise control of wall thickness:

- Excess thickness wastes raw materials, increasing costs unnecessarily.

- Insufficient thickness compromises strength, leading to higher rejection and return rates.

By using the WTT Wall Thickness Tester, manufacturers can optimize wall thickness to the minimum safe level, achieving both cost savings and sustainability goals by reducing plastic or glass consumption.

03

3. Quality Consistency & Compliance

- Wall thickness testing ensures bottles meet uniform quality standards, avoiding weak spots or deformations.

- Consistency in thickness improves brand reputation by delivering reliable products to customers.

- Documentation of thickness testing helps manufacturers pass audits and meet customer specifications.

In global packaging markets, compliance with international standards (ISO, ASTM, FDA requirements) is a must.

Get in touch

No. 5577 Gongyebei Rd, Licheng, Jinan, 250109, Shandong, P.R.C.

marketing@celtec.cn

+86 185 6001 3985